Marine Grade Plastics

Why Choose Marine‑Grade Plastics?

From HDPE swim platforms to PVC foam boat boards, our materials outlast wood and metal without rotting, rusting or warping. Brands like StarBoard®, Seaboard® and our own Trident® panels deliver slip‑resistant finishes, vibrant colours and CNC‑ready consistency for every boating or dock project.

Top Marine Applications

Boat Decking & Swim Platforms

Lightweight HDPE and Trident wood‑grain panels offer barefoot traction while resisting salt spray and UV.

Dock Fenders & Bumpers

Impact‑absorbing HDPE strips protect hulls and pilings, reducing maintenance costs for marinas.

Cabinetry & Hatches

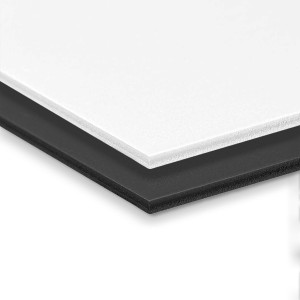

PVC foam board machines cleanly and weighs 30 % less than plywood—zero water uptake.

Windows & Windscreens

Optically clear acrylic shields crew from spray while providing long‑term UV stability.

Benefits at a Glance

Engineered for years of sun and sea exposure without chalking or cracking.

Closed‑cell structure means no water absorption—ever.

Cuts, routes and CNCs with standard woodworking tools.

No painting needed; scratches never reveal contrasting layers.

Sustainability Features

- 100 % recyclable HDPE & PVC

- Extended service life reduces waste

- Lightweight sheets lower shipping emissions

- Manufactured in the USA supply chain

Marine Plastics FAQ

Is marine‑grade HDPE really stronger than wood?

Yes. Marine‑grade HDPE maintains its strength in wet, salty environments and will not rot, warp or delaminate like plywood.

Can PVC foam board be used for boat cabinets?

Absolutely. Closed‑cell PVC foam is lightweight, waterproof and easy to CNC—perfect for interior doors and cabinets.

How do I cut marine plastic board?

Use carbide woodworking blades. Standard circular saws or CNC routers provide clean edges; slow feed speeds avoid melting.

Do you ship marine plastics across Florida?

Yes. We stock Jacksonville, Orlando and Clearwater branches—same‑day pickup or rapid delivery statewide.