Browse By Application

Explore industrial plastic materials by application with Farco Plastics. From outdoor signage and marine environments to manufacturing, industrial equipment, and construction projects, our plastics are engineered to deliver reliable performance where it matters most.

Use this applications overview to quickly identify the right plastic sheet, rod, or tube based on your environment, performance requirements, and fabrication needs. If you’re unsure which material is best, our team can help you match the ideal plastic to your project.

Primary Plastic Applications

Signage & Graphics

- Indoor and outdoor retail signage

- Backlit displays and wayfinding

- Printed graphics and POP displays

- Channel letters and dimensional signs

Common materials: Acrylic, Polycarbonate, PVC, ACM, HDU

Marine & Outdoor

- Boat components, panels, and covers

- Dock boards, bumpers, and fender systems

- Waterfront and coastal signage

- Outdoor furniture and structures

Common materials: HDPE, Marine-grade polymer sheet, UHMW, PVC

Manufacturing & Industrial

- Wear strips, guides, and rails

- Bearings, bushings, and gears

- Conveyor components and guards

- Chemical-resistant tanks and parts

Common materials: UHMW, Acetal, Nylon, Polypropylene, ABS

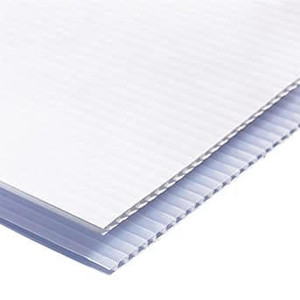

Construction & Architectural

- Protective glazing and safety barriers

- Wall panels, partitions, and guards

- Decorative and architectural features

- Weather-resistant exterior components

Common materials: Polycarbonate, Acrylic, PVC, ACM

Why Browse Plastics by Application?

Better Performance & Fit

- Match plastics to real-world conditions (UV, moisture, impact, chemicals)

- Select materials designed for specific environments and loads

- Reduce premature failure and unplanned downtime

- Improve part life, reliability, and safety in the field

Simplified Material Selection

- Start with the application, then narrow by material type

- Quickly compare options for signage, marine, industrial, or construction

- Identify plastics that are easier to machine, weld, or fabricate

- Leverage support from Farco’s application and material specialists

Material Selection Tips

- Define exposure: UV, weather, saltwater, chemicals, or high impact.

- Confirm mechanical needs: stiffness, toughness, and wear resistance.

- Check fabrication method: machining, thermoforming, bonding, or welding.

- Review compliance needs: food contact, flame ratings, or industry standards.